The Basics of Waterproofing

Nothing is more essential to a successful rooftop solar installation than making sure the holes you drill into the roof do not develop leaks. Water intrusion is the leading cause of construction-related litigation and can cause substantial damage. Leaks that don’t get addressed early can eventually compromise the integrity of the building envelope. Mold created by undetected moisture can damage human health and cost thousands or tens of thousands of dollars to fix. Quality waterproofing is the best insurance you can buy.

Helping You Learn About Waterproofing

To avoid a host of problems down the road, it is essential that solar designers, installers, and the solar industry as a whole follow roofing best practices. Quick Mount PV was founded in 2006 to address this objective with superior, innovative rooftop mounting products. To help ensure installers are properly educated on codes, standards, and best practices, IronRidge offers a full range of in-person and web-based training programs to help ensure every rooftop installation is 100% waterproof.

Following is basic information about waterproofing, code compliance, the use of galvanized steel, and maintaining roof warranties. While primarily intended as a primer for solar professionals, we believe this information can also prove useful to home and business owners who are making decisions about solar PV and/or solar water heating systems. IronRidge offers a comprehensive professional training program, described here.

The Challenge of Rooftop Solar

Sound waterproofing practices are not a recent innovation. Professional roofers have followed proven, often painstaking installation measures to prevent the possibility of leaks for flashed penetrations for decades. Historically, roofs had only a few penetrations for plumbing vents and gas vent stacks, but a typical rooftop solar PV installation requires dozens of penetrations. Making a solar installation economically feasible requires a quick and easy way to mount the array while ensuring waterproof penetrations.

Getting Beyond Just Sealant

Those who pioneered off-grid solar installations back in the 1980s didn’t fully appreciate the importance of flashed penetrations for a proper waterproofing solution. Those early installers often used sealant as the only waterproofing protection. However, sealants are susceptible to breakdown from the sun’s ultraviolet rays, oxidation, expansion, and contraction with changing temperatures. Small but constant flexing of the attachment over the years as the sealant ages, will eventually cause cracks and become compromised.

Today, solar system designers and installers recognize the importance of using metal flashing and following roofing best practices. Likewise, local building inspectors in most jurisdictions now understand that all lag screws securing solar roof mounts need to be properly flashed and waterproofed in accordance with roofing manufacturer requirements.

Are You Up To Code?

The ability to install rooftop solar systems that consistently meet waterproofing code requirements rests on understanding the relationship between code, roofing manufacturers, and best practice guidelines. This knowledge can make the difference between passing and failing an inspection, and helps maintain any roof warranties as well as reduce long-term liability.

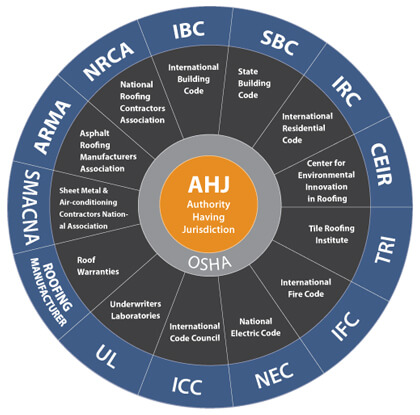

Quick Mount PV created the Wheel of Accountability to help solar designers and installers better understand the relationships between relevant codes, standards and best practices, guidelines that impact rooftop structures, and waterproofing.

The AHJ (Authority Having Jurisdiction) – typically the local building department – is at the center of the Wheel. The AHJ has the final say on how rooftop solar systems will be installed. The AHJ is empowered to interpret codes and standards and enact special requirements that address climatic, geological, seismological, or topographical conditions unique to that area.

OSHA establishes workplace safety requirements and can shut down any job site or find an installer for unsafe workplace practices.

The National Fire Protection Association (NFPA) publishes the National Electric Code that governs equipment-grounding requirements for PV systems. UL develops the UL 2703 standard for rack-mounted PV systems which outlines the proper methods for ensuring a reliable equipment ground for the modules and rack to minimize the potential for shock or fire hazard in the event of an accidental fault. Building codes are developed by the International Code Council (ICC) – which publishes the International Building Code and International Residential Codes, which are used as the basis for almost every State Building Code. Building codes require that all roof penetrations be waterproofed with flashing that complies with the roofing manufacturer’s requirement. The NRCA and ARMA publish installation guidelines used by the overwhelming majority of shingle manufactures, and the Tile Roofing Institute publishes flashing guidelines used by the vast majority of tile manufacturers.

The ICC offers testing and certification for roof attachments and many Quick Mount PV products have the ICC Evaluation Service Report certification.

The roofing manufacturer is included in the Wheel of Accountability, as the building code establishes the manufacturer as the entity that determines proper flashing procedure. It is necessary to follow roofing manufacturer flashing installation instructions to comply with code and maintain the roof warranty

Key Players and Building Codes

Below are some of the key players and relevant building codes in the Wheel of Accountability.

Associations

NRCA

National Roofing Contractors Association roofing manuals provide time-tested, best-practice guidelines and technical information concerning the materials, design and installation of roof systems. The NRCA derives its information from knowledgeable, practicing roofing contractors located throughout the U.S.

NRCA website

ARMA

The Asphalt Roofing Manufacturers Association represents about 95% of North America’s asphalt (bituminous-based) roofing manufacturing companies and their raw material suppliers. ARMA spearheads industry research and development and provides information on modern asphalt roofing materials and practices to building and code officials, regulatory agencies and allied trade groups.. ARMA’s “The Asphalt Roofing Residential Manual – Design and Application Methods” is required for anyone who wants to know how to work on a roof without voiding its warranty.

ARMA website

CEIR

The Center for Environmental Innovation in Roofing (CEIR) established the CEIR PV Taskforce to increase communication between the roofing and solar industries. The Taskforce aims to drive higher quality combined solar energy roofing systems through best practices and industry standards. The Center PV Taskforce has developed PV installation guidelines for low slope membrane roofs, low slope metal roofs, and steep slope shingle roofs.

CEIR website

TRI

The Tile Roofing Institute is the recognized authority on best practice guidelines for flashing and waterproofing on tile roofing systems. The TRI publishes installation guides for tile roofs and flashing methods for cold and warm weather climatic regions. The TRI trains roofing installers, inspectors and industry professionals on proper, code-approved methods for installing concrete and clay tile roofs. TRI is dedicated to growing the tile roofing market through technical expertise, training, and building awareness for the many benefits of tile.

TRI website

SMACNA

The Sheet Metal and Air-conditioning Contractors National Association, is dedicated to flashing details and exterior metals and publishes the “Architectural Sheet Metal Manual”. First published in 1965, the manual addresses all aspects of flashing and building envelope metals, with an emphasis on preventing building moisture intrusion. The manual is updated on a regular basis and contains details and specifications for the vast majority of situations requiring flashings.

SMACNA website

UL

Underwriters Laboratory develops widely accepted standards for modules, inverters, and PV racking systems. The UL 2703 standard establishes requirements for bonding and grounding, corrosion, structural capacity, and fire classification for PV racking systems UL certification does not guarantee the product will perform acceptably, but a properly designed and installed UL 2703 listed racking system should considerably reduce the potential of safety problems that can plague poor quality systems.

UL website

ICC

The International Code Council (ICC) is a nonprofit organization dedicated to developing building codes that help permitting officials and inspectors validate the safety of the systems installed on residential and commercial structures.

ICC website

IFC

The 2012 International Fire Code introduced spacing “setbacks” for PV arrays from the ridge, rakes, hips and valleys, and other obstacles such as gas vents, chimneys, access hatches, and skylights. These new setback requirements are intended to provide ventilation access and pathways for firefighters to clear smoke and noxious gasses in structures during a fire event. These setback requirements have resulted in less space for solar systems on residential structures, and are being re-evaluated by fire and solar industry subject matter experts to determine if the setback requirements can be reduced to allow more solar panels on a home.

The IFC on the ICC website

NEC

The National Electric Code (NEC) is developed by the National Fire Protection Association and serves as the benchmark code for safe electrical design, installation, and inspection to protect people and property from shock and fire hazards. The NEC outlines proper wiring and grounding of PV systems.

THE NEC on the NFPA website

AHJ

In construction, the Authority Having Jurisdiction (AHJ) is the governmental agency or sub-agency that regulates the construction process. In most cases, the AHJ is the municipality in which the structure is located. The AHJ’s building department has permitting officials and inspectors who evaluate system design and installation to ensure solar systems meet the applicable building, fire, electrical, and/or plumbing codes.

Codes

Almost every state utilizes the International Building Code (IBC) and International Residential Code (IRC) as the basis for their own State Building Codes (SBC). The IRC governs new construction in single or two family structures of three stories or less and the IBC governs all other structures. Amendments vary from state to state based on issues specific to regional and local conditions.

State Building Codes form the framework for local fire, building, housing, property maintenance, plumbing, electrical, energy, and mechanical codes.

IBC

The International Building Code addresses waterproofing of penetrations in the following sections:

- 1503.2. Flashing shall be installed in such a manner so as to prevent moisture entering the wall and roof through joints in copings, through moisture-permeable materials and at intersections with parapet walls and other penetrations through the roof plane

- 1503.2.1 Flashing shall be installed at wall and roof intersections, at gutters, wherever there is a change in roof slope or direction; and around roof openings. Where flashing is of metal, the metal shall be corrosion-resistant with a thickness of not less than 0.019 inch.

- 1506.1 The requirements set forth in this section apply to the application of roof-covering materials specified herein. Roof coverings shall be applied in accordance with this chapter and the manufacturer’s installation instructions. Installation of roof coverings shall apply to the applicable provisions of Section 1507.

- 1506.2 Compatibility of Materials. Roofs and roof coverings shall be of materials that are compatible with each other and with the building or structure to which the materials are applied.

- 1506.4 Product Identification. Roof covering materials shall be delivered in packages bearing the manufacturers’ identifying marks and approved testing agency labels required in accordance with Section 1505 Bulk shipments of materials shall be accompanied with the same information issued in the form of a certificate or on a bill of lading by the manufacturer.

- 1507.2.9 Flashings. Flashings for asphalt shingles shall comply with this section. Flashing shall be applied in accordance with this section and the asphalt shingle manufacturer’s printed instructions.

- 1507.8.7 At the juncture of the roof and vertical surfaces, flashing and counter flashing shall be provided in accordance with the manufacturer’s written installation instructions, and where of metal, shall not be less than 0.019 inch (0.48mm) (No, 26 galvanized sheet gage) corrosion-resistant metal.

IRC

The International Residential Code addresses waterproofing of penetrations in the following sections:

Chapter 23 Solar Systems

- M2301.2 Installation: Installation of solar energy systems shall comply with Sections M2301.2.1 through M2301.2.9.

- M2301.2.2 Roof-mounted collectors: The roof shall be constructed to support the loads imposed by roof-mounted solar collectors. Roof-mounted solar collectors that serve as a roof covering shall conform to the requirements for roof coverings in Chapter 9 of this code. Where mounted on or above roof coverings, the collectors and supporting structure shall be constructed of noncombustible materials or fire-retardant-treated wood equivalent to that required for the roof construction.

- M2301.2.7 Roof and wall penetrations: Roof and wall penetrations shall be flashed and sealed in accordance with Chapter 9 of this code to prevent entry of water, rodents and insects.

- R901.1 Scope: The provisions of this chapter shall govern the design, materials, construction and quality of roof assemblies.

- R903.1 General: Roof decks shall be covered with approved roof coverings secured to the building or structure in accordance with the provisions of this chapter. Roof assemblies shall be designed and installed in accordance with this code and the approved manufacturer’s installation instructions such that the roof assembly shall serve to protect the building or structure.

- R903.2 Flashing: Flashings shall be installed in a manner that prevents moisture from entering the wall and roof through joints in copings, through moisture-permeable materials and at intersections with parapet walls and other penetrations through the roof plane.

- R903.2.1 Locations: Flashings shall be installed at wall and roof slope or direction around roof openings. Where flashing is of metal, the metal shall be corrosion-resistant with the thickness of no less than 0,019 inch (0.5 mm) (No. 26 galvanized sheet).

- R905.2.8 Flashing: Flashing for asphalt shingles shall comply with this section.

- R905.2.8.1 Base and cap flashing (p441). Base and cap flashing shall be installed in accordance with manufacturer’s instructions.

- R905.2.8.4 Other Flashing: Flashing against a vertical front wall, as well as soil stack, vent pipe and chimney flashing, shall be applied according to the asphalt shingle manufacturer’s printed instructions.

SBC

State Building Codes typically adopt language in whole or in part from the IBC and IRC, as with the California Building Standards Code of Regulations, Title 24, Section 1503, which advises the use of appropriate flashing in key locations for weather proofing:

- In Section 1503.2 “Flashings shall be installed in such a manner so as to prevent moisture from entering the wall and roof through joints in copings, through moisture-permeable materials, and at intersections with parapet walls and other penetrations through the roof plane.”

- In Section 1503.2.1 Flashings shall be installed at wall and roof intersections; wherever there is a change in roof slope or direction; and around roof openings. Where flashing is of metal, the metal shall be corrosion-resistant with a thickness of not less than 0.019 inch (No. 26 galvanized steel).

What About Galvanized?

Even when painted, galvanized steel flashing and mounts can be expected to last only about 15 years according to the Sheet Metal and Air Conditioning National Association’s (SMACNA) Architectural Sheet Metal Manual. A primary reason that Quick Mount PV’s flashed mounts last much longer than galvanized steel products is due to the fact that our products are constructed with corrosion resistant aluminum and all exposed hardware is stainless steel. This combination of materials provides an estimated life of 50 years. The SMACNA manual allows for, at minimum, 24-gauge galvanized steel but stipulates that the flashing must be painted as well.

PV modules are expected to provide power for 20-30 years, and in some areas even longer. For this reason, it is usually a good idea to install new shingles or tile underlayment prior to solar installation so that you won’t have to reroof down the road. For this same reason, using a flashed mounting system that lasts as long as the PV modules makes the most sense.

SMACNA’s manual lists the pros and cons of a range of flashing materials, including stainless steel, copper, lead, aluminum, and galvanized steel. Stainless is considered 100-year compatible, but is very expensive and relatively difficult to fabricate in the field. Copper and lead will last nearly as long and are easy to field fabricate, but they are expensive, and lead is toxic to work with on a regular basis. Aluminum is considered 50-year compatible, is much less costly and non-toxic, but is still not as easy to field fabricate as galvanized steel, copper and lead. Because Quick Mount PV flashings are fabricated to the right size, there’s no need for any metal cutting on the roof.

Galvanized steel flashings are inexpensive, readily available, and easy to fabricate at the job site. However, many roofing manufacturers’ instructions warn that using galvanized flashings may void their warranty altogether. If you must use galvanized steel flashings, be sure to carefully read the roof warranty. Some warranties may accept galvanized flashing of 24 gauge while at the same time rejecting slightly thinner 26 gauge.

One more note on the use of galvanized steel: The Unified Facilities Guide Specifications for USACE (US Army Corps of Engineers), NAVFAC (Naval Facilities Engineering Command), AFCESA (Air Force Civil Engineer Support Agency), and NASA (National Aeronautics and Space Administration), forbid the use of galvanized flashings, as they do not have the life expectancy required to last as long as their roofs.

For more details, visit: www.smacna.org

Maintaining Roof Warranties

Roofs can have two types of warranties: a material warranty and a workmanship warranty. In some cases the workmanship warranty is covered by the roofing manufacturer, but most of the time, workmanship is warrantied by the contractor. If the manufacturer or contractor is no longer in business, then the relevant warranty may no longer be in place.

QuickMount products are approved by leading roofing manufacturers, and won’t void the material and/or workmanship warranties. For more information contact our Sales Team.

Consulting a Roofer

Whenever the material or labor warranty is still valid, as is the case with newer construction, it is advisable to consult the roofer of record prior to solar installation. Labor warranties can vary significantly. Often the roofing contractor will void their workmanship warranty if another trade modifies the roof in any way, however, they will often maintain these warranties if you contract with them to install the flashed roof attachments. At the very least, allow the roofer the opportunity to inspect and approve the modifications you make.

If the roofer of record is unknown or unavailable, we recommend getting another roofer to take a look and advise and assist as needed.

Maintaining the Manufacturer’s Warranty

Once a new roof has been installed, any subsequent modification will be known as a “retrofit.” Not voiding the manufacturer’s warranty during an installation on an existing roof requires knowledge and skill. Poorly executed retrofits are the most common cause of warranty issues.

The manufacturer’s instructions will spell out exactly what does and does not void the warranty of their roofing product. If you have any questions or uncertainty, consult a professional roofer.

Installers must adhere not only to the manufacturer’s list of requirements, but must also follow roofing industry general standards and best practices for waterproofing, as spelled out in guidelines provided by roofing authorities such as SMACNA, ARMA, TRI, and the NRCA.

Code-Compliance is Built Into QuickMount Products

Studying and understanding the relevant codes, standards, and best practice installation guidelines from all of the above listed organizations was the starting point in the design of QuickMount’s mounting products. We proactively monitor all developments in the relevant codes and guidelines to ensure that our customers have the highest quality, longest lasting, code compliant waterproofing possible.

When you design and install QuickMount products correctly, you can rest assured that you are up to code and your system will stay watertight for the life of the PV system. Furthermore, if you follow the roofing manufacturer’s flashing instructions, you minimize the possibility of voiding the roofing material warranty.

Digging In