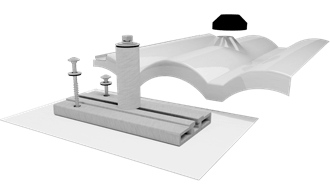

Tile Replacement Mount

The Tile Replacement Mount provides a fast and easy way to install solar on tile roofs while protecting against water intrusion. Simply remove the tile and replace it with the Tile Replacement Mount. Works with standard curved and flat tile roofs, and standard rail-based racking systems.

Flashed at both the deck and top levels, the Tile Replacement Mount is fully engineered to meet code requirements and industry best practices. The Tile Replacement Mount features our patented Elevated Water Seal Technology® for optimal waterproofing. Base mount sold separately from flashing and post.

For unique tile shapes, use the Universal Tile Flashing & Post with the QMTR-BM Base Mount. Its malleable 18×18-inch flashing fits over any existing tile. Download instructions.

Available in aluminum mill and black finishes.

Features

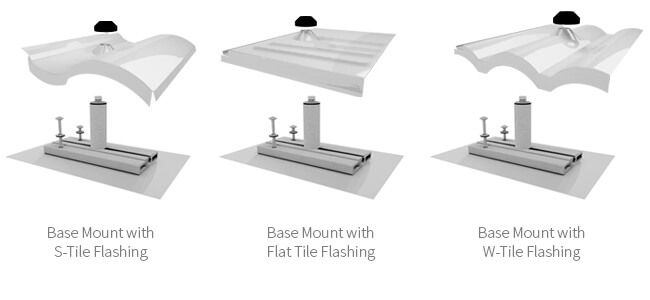

- Versatile: Works with Flat, S-shaped and W-shaped tiles

- Flexible: Works with all standard rail-based racking systems

- Simple and clean: No messy tile grinding or cutting

- Double flashed: Flashed at deck and tile levels for code compliance

- Waterproof: Features QBlock® Elevated Water Seal Technology®

- Flashings pre-treated and ready for paint, if desired

- Post and flashing sold separately from base mount

- Creates replacement tiles on the job

- Meets or exceeds tile roofing best practices

- 100% IBC compliant

- All fasteners and hardware included

- 25-year warranty

Resources

- Installation Guide

- Three-Course Method (Waterproofing)

- Base Mount Positioning Template Guide

- Engineering Report

- Base Mount CAD Blocks (DWG, PDF)

- S-Tile Flashing CAD Blocks (DWG, PDF)

- W-Tile Flashing CAD Blocks (DWG, PDF)

- Flat Tile Flashing CAD Blocks (DWG, PDF)

Certification Letters

Rail Compatibility

| Ninja Column 1 | Ninja Column 2 |

|---|---|

| Included in base kit | 12″ x 7½” flashing and Tile Replacement Base EPDM-bonded stainless steel sealing washer, 5/16″ x ¾” x 2 2 x steel T-30 button head structural screw, 5/16″ x 4″ |

| Included in flashing kit | W-tile flashing & 4″ post, aluminum or S-tile flashing & 3¼” post, aluminum or Flat tile flashing & 3¼ post, aluminum 1″ serrated flange hex-head cap screw EPDM-bonded stainless steel sealing washer, 5/16″ x 1¼” EPDM Counter flashing collar 5/16″ x 1″ fender washer 5/16″ split-lock washer 1″ hex-head cap screw |

| Flashings available | Flat, S-Tile, and W-Tile |

| Tools needed for installation | Stud Finder Tape measure Utility Knife Drill with 7/8″ bit Impact gun with T-30 Torx bit Calipers Caulking gun One tube of sealant compatible with roofing materials Extra pieces of underlayment or materials for 3-course method Hand broom Stapler Roofer’s bar or shingle ripper |

| Applicable roof types | Flat, S-shaped and W-shaped tiles |

| Available finishes | Aluminum mill Black |

Tile Replacement Mount: See How It Works

Installing the Tile Replacement Mount

Waterproofing Technology for Tile Roofs

Tile Roofs (Webinar)

Tile Roof Waterproofing Methods

All QuickMount tile mounting products are designed to comply with the roofing best practices listed by the Tile Roofing Institute (TRI) for tile penetration flashing (MC-02). The photos below show our QBase Universal Tile Mount. The same waterproofing methods are recommended for all of our tile mounting products. For more info go to www.tileroofing.org.

Three-Course Method

If permitted by the building inspector, the three-course method may be an option for waterproofing the deck flashing. This process uses a layer of asphalt roof cement (approved by the roof manufacturer), a layer of reinforcing fabric, and another layer of asphalt roof cement to seal the flashing to the felt paper. Click here to download step-by-step instructions to use the three-course method with our tile roof products. (PDF 617K)

Felt Paper Bibbing Method

In retrofit installations where the standoff and primary flashing do not fall in a position that is close to the overlap of felt paper, an approach that is sometimes called “bibbing” can be used. When the overlapping drip edge of the felt paper ends in the tile course above the penetration, a separate piece of felt paper is positioned under the battens and overlapping felt, which then extends down to bib around the penetration and over the deck flashing.

UL 2703 Certification

All IronRidge® Systems have been listed to UL 2703, the standard for evaluating solar mounting systems. This ensures they maintain strong electrical and mechanical connections over an extended period of time in extreme outdoor environments.

25-Year Warranty

IronRidge® products come with a 25-year warranty, guaranteeing they will be free of defects in materials and manufacturing which materially impair the use of the products for the purposes for which they were designed.