Launched in 2017, IronRidge designed the CAMO™ hidden end clamp using our rigorous engineering process, which included extreme laboratory stress testing with humidity exposure, thermal cycling, and more. CAMO™ passed with flying colors.

Sometimes, however, mother nature teaches us something new and informs the future and for what we design and test. Even building codes and building designs have evolved over time to account for hurricane-force winds, potential earthquakes, and other extreme natural factors and events.

Last year, we became aware of a few instances of premature corrosion and immediately began a country-wide investigation. Through this investigation, we discovered additional occurrences of accelerated corrosion located solely in highly corrosive environments. IronRidge contacted the CPSC to notify them and seek guidance on remediation.

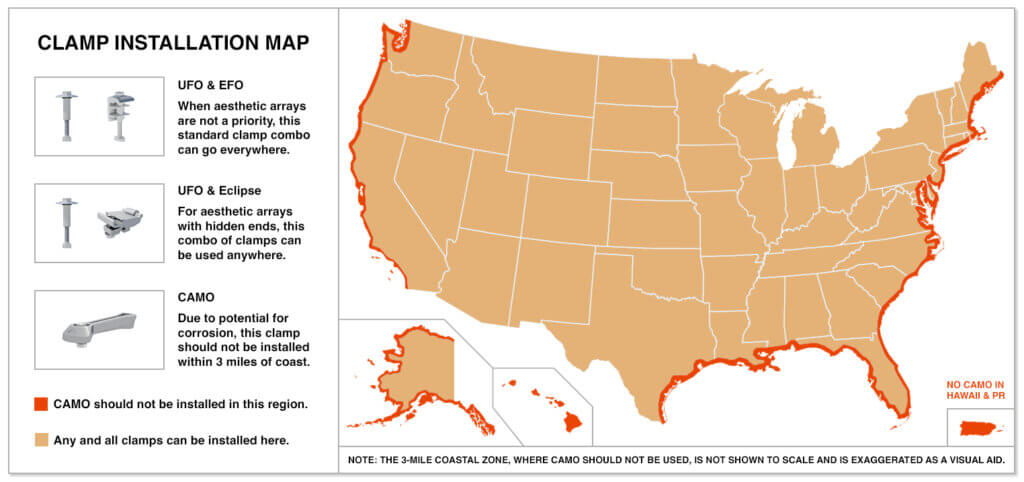

We began internal testing under more extreme conditions, had these testing results verified by a third-party engineering firm, and reported them to the CPSC. We also engaged independent experts to remove any potential bias in developing the best solution. Through these efforts, it was determined that the effect is limited to extreme corrosion environments, within 3 miles of a saltwater coast, or 2 miles from a saltwater bay or inlet.

A core value of IronRidge is to always “Do the Right Thing,” so we are making sure that we provide those impacted installers with free retrofit product as well as compensating them for their labor expenditures.

If you are an impacted installer, or know one, please visit the retrofit landing page to learn more.